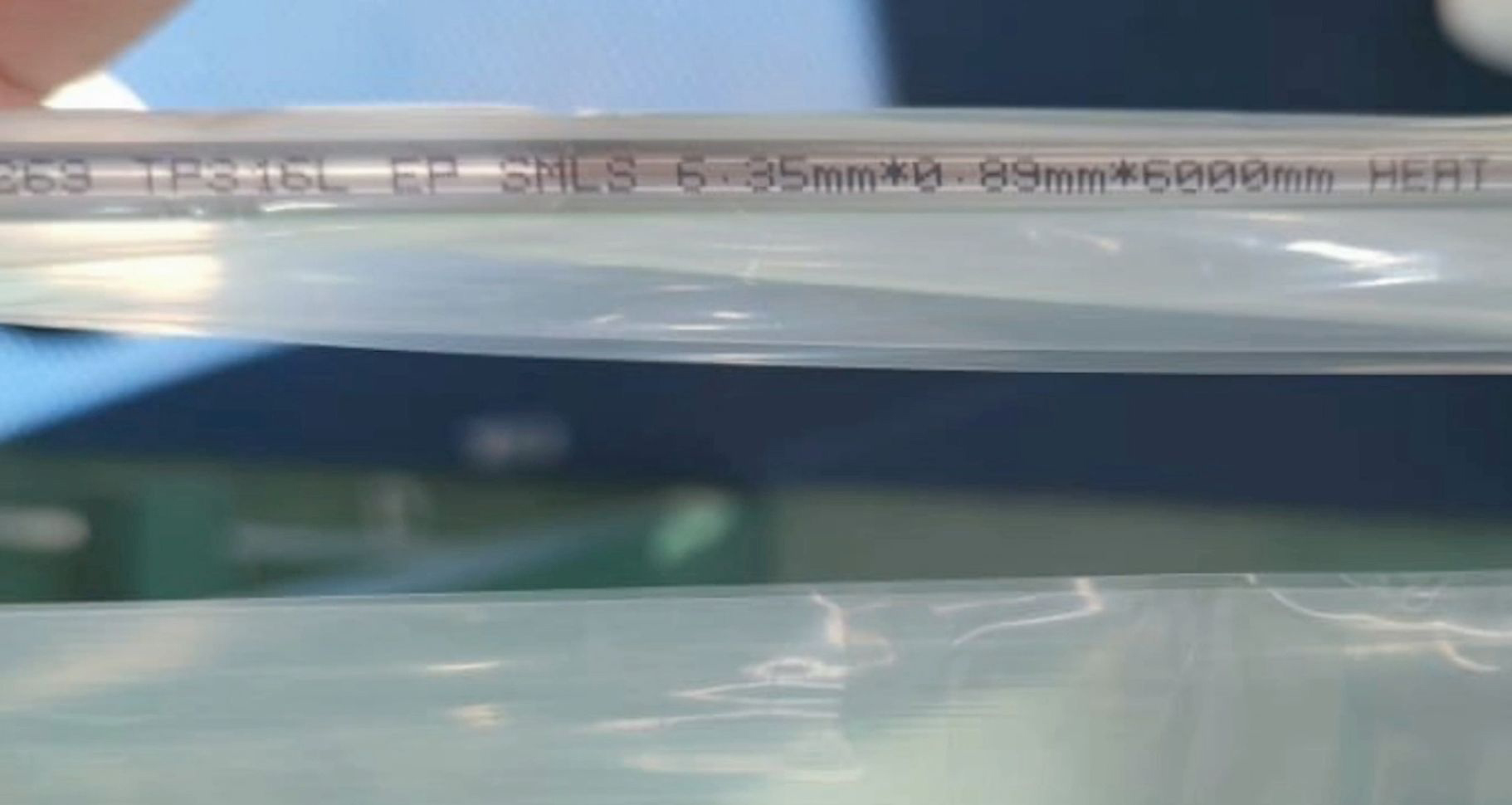

ʻO ka ʻili uila (EP) Seamless Tube

He aha ka Electropolishing?

ElectropolishingHe kaʻina hana hoʻopau electrochemical e hoʻoneʻe i kahi ʻāpana lahilahi o ka mea mai kahi ʻāpana metala, maʻamau he kila kuhiliʻole a i ʻole nā mea like. Ke waiho nei ke kaʻina hana i kahi ʻālohilohi, ʻoluʻolu, ultra-maʻemaʻe.

Also ikehoʻolāʻau electrochemical, hoʻoliʻi anodica i ʻolehoʻopololei electrolytic, He mea pono loa ka electropolishing no ka poli a me ka wehe ʻana i nā ʻāpana palupalu a i ʻole nā geometries paʻakikī. Hoʻomaikaʻi ʻo Electropolishing i ka hoʻopau ʻana i ka ʻili ma ka hōʻemi ʻana i ka roughness o ka ʻili a hiki i 50%.

Hiki ke noʻonoʻo ʻia ka electropolishinghoʻohuli electroplating. Ma kahi o ka hoʻohui ʻana i kahi uhi lahilahi o nā ion metala i hoʻopiʻi maikaʻi ʻia, hoʻohana ka electropolishing i ke au uila e hoʻoheheʻe i kahi ʻāpana lahilahi o nā ion metala i loko o kahi hopena electrolyte.

ʻO ka electropolishing o ke kila kila ka hoʻohana maʻamau o ka electropolishing. ʻO ke kila kila kila i hoʻomaʻemaʻe ʻia, ʻālohilohi, ultra-maʻemaʻe e kūʻē i ka ʻino. ʻOiai kokoke i nā metala e hana, ʻo nā metala electropolished maʻamau he 300- a me 400-series stainless steel.

ʻO ka hoʻopau ʻana o ka electroplating he mau kūlana like ʻole no ka hoʻohana ʻana i nā noi like ʻole. Pono kēia mau noi i ka laulā waena o ka hoʻopau. ʻO ka Electropolishing kahi kaʻina hana me ka hoʻohaʻahaʻa loa o ka Electropolished Stainless Steel Pipe. ʻO kēia ka mea i ʻoi aku ka pololei o nā paipu i nā ana a hiki ke hoʻokomo ʻia ka Ep Pipe me ka pololei i nā ʻōnaehana koʻikoʻi e like me nā noi ʻoihana lāʻau lapaʻau.

Loaʻa iā mākou kā mākou mau mea hana polishing ponoʻī a hana i nā paipu electrolytic polishing e hoʻokō i nā koi o nā kahua like ʻole ma lalo o ke alakaʻi ʻana o ka hui ʻenehana Korea.

ʻO kā mākou EP Tube ma ISO14644-1 Class 5 maʻemaʻe kūlana lumi, hoʻomaʻemaʻe ʻia kēlā me kēia paipu me ka ultra high purity (UHP) nitrogen a laila hoʻopaʻa ʻia a paʻa pālua. Hāʻawi ʻia ka palapala hōʻoia e hoʻokō ai i nā kūlana hana o ka paipu, haku mele mele, hiki ke ʻike i nā mea, a me ka ʻili o ka ʻili kiʻekiʻe no nā mea āpau.

Hōʻike

ASTM A213 / ASTM A269

ʻOka a me ka paʻakikī

| Hana Hana | ʻOʻoʻoleʻa Kuloko | ʻOʻoʻoleʻa waho | ʻO ka paʻakikī max |

| HRB | |||

| ASTM A269 | Ra ≤ 0.25μm | Ra ≤ 0.50μm | 90 |

Huihui Elemental Hui o ka Tube

Hōʻike 16939(1)

Kaʻina hana

ʻO ka ʻōwili anu / kiʻi anu / Annealing / Electropolished

Papa Mea

TP316/316L

Hoʻopili

Ua hoʻomaʻemaʻe ʻia kēlā me kēia paipu hoʻokahi e ke kinoea N2, hoʻopaʻa ʻia ma nā ʻaoʻao ʻelua, hoʻopili ʻia i loko o nā ʻeke ʻelua maʻemaʻe maʻemaʻe a me ka hope i loko o ka pahu lāʻau.

EP Tube Clean Room

Nā Kūlana lumi maʻemaʻe: ISO14644-1 Papa 5

Palapala noi

Semi-conductor/ Hōʻike/ Meaʻai · lāʻau lapaʻau · mea hana bio/ ʻO ka pipeline maʻemaʻe maʻemaʻe maʻemaʻe / Lako hana ikehu lā

Palapala Hoohanohano

ISO9001/2015 Kūlana

ISO 45001/2018 Kūlana

Palapala PED

TUV Hydrogen compatibility test certificate

FAQ

ʻO ka pahu kila kila 316L kahi ʻano o ka paipu kila kila e hoʻomaʻamaʻa ana i ka ʻili kūikawā i kapa ʻia ʻo electropolishing (EP). Eia nā kikoʻī nui:

- Mea Hana: Hana ʻia ia mai ka 316L stainless steel, he haʻahaʻa haʻahaʻa ka carbon content i hoʻohālikelike ʻia me 304 stainless steel. ʻO kēia ka mea i ʻoi aku ka pale ʻana i ka corrosion a kūpono i nā noi i loaʻa nā pilikia sensitization.

- Hoʻopau i ka ʻili: ʻO ka electropolishing ka hoʻoheheʻe ʻana i ka paipu i loko o kahi ʻauʻau ʻauʻau electrolyte i hoʻoiho uila. Hoʻopau kēia kaʻina hana i nā hemahema ma luna a i ʻole ma lalo pono o ka ʻili o ka paipu, e loaʻa ana i kahi hoʻopau ʻoluʻolu a like. Ua hōʻoia ʻia ka ʻino o ka ʻili i loko o ka nui o 10 micro-inches Ra.

- Nā noi:

- ʻoihana lāʻau lapaʻau: Hoʻohana ʻia no nā noi maʻemaʻe ultra-kiʻekiʻe ma muli o kona maʻemaʻe a me ka pale ʻana i ka corrosion.

- Ka Hana Kemika: Laina laina no ka ike ana i ka H2S.

- Pūnaehana Paipu Hoʻomaʻemaʻe: He kūpono no nā meaʻai a me nā mea inu.

- Hana Semiconductor: He mea koʻikoʻi ka hoʻomaʻamaʻa maikaʻi ʻana o ka paipu.

- Nā palapala hōʻoia: ʻO nā kikoʻī hoʻomalu no nā paipu electropolished ʻo ASTM A269, A632, a me A1016. Hoʻomaʻemaʻe ʻia kēlā me kēia paipu me ka ultra-high purity nitrogen, capped, a pālua ʻia i nā kūlana lumi maʻemaʻe ISO Class 4.

Hāʻawi ka Electropolished tubing i nā pono he nui:

- Kū'ē Kū'ē: Hoʻopau ke kaʻina hana electropolishing i nā hemahema o ka ʻili, hoʻonui i ke kūʻē ʻana o ka mea i ka corrosion a me ka lua.

- Hoʻopau maʻemaʻe: ʻO ka hopena e like me ke aniani e hōʻemi ai i ka friction, e maʻalahi ka hoʻomaʻemaʻe a mālama. He mea koʻikoʻi kēia no nā noi i ka lāʻau lapaʻau, ka hoʻoili ʻana i ka meaʻai, a me nā ʻoihana semiconductor.

- Hoʻomaikaʻi ʻia ka Maʻemaʻe: He liʻiliʻi ka liʻiliʻi o nā paipu electropolished a me ka micro-roughness, e hōʻemi ana i ka ulu ʻana o ka maʻi bacteria. He kūpono lākou no nā hana maʻemaʻe.

- Hoʻemi ʻia ka Contaminant Adhesion: Hoʻopau ka ʻili maʻemaʻe i nā ʻāpana a me nā mea haumia mai ka hoʻopili ʻana, e hōʻoia i ka maʻemaʻe o ka huahana.

- Hoʻonui Aesthetics: ʻO ka hiʻohiʻona i poni ʻia ke nānā aku a kūpono no nā noi kiʻekiʻe.

Hoʻohana mau ʻia nā paipu electropolished i nā wahi koʻikoʻi kahi e pono ai ka maʻemaʻe, ka pale ʻana i ka corrosion, a me nā ʻili laulima.

| ʻAʻole. | Nui | |

| OD(mm) | Thk(mm) | |

| 1/4″ | 6.35 | 0.89 |

| 3/8″ | 9.53 | 0.89 |

| 1/2″ | 12.70 | 1.24 |

| 3/4″ | 19.05 | 1.65 |

| 3/4″ | 19.05 | 2.11 |

| 1″ | 25.40 | 1.65 |

| 1″ | 25.40 | 2.11 |

| 1-1/4″ | 31.75 | 1.65 |

| 1-1/2″ | 38.10 | 1.65 |

| 2″ | 50.80 | 1.65 |

| 10A | 17.30 | 1.20 |

| 15A | 21.70 | 1.65 |

| 20A | 27.20 | 1.65 |

| 25A | 34.00 | 1.65 |

| 32A | 42.70 | 1.65 |

| 40A | 48.60 | 1.65 |